Certainly! Ensuring the correct thickness of a powder coating using a Powder Spray Gun is crucial for achieving high-quality results. Here are some methods to achieve this:

Choose the Right Powder Spray Gun:

Use a high-quality spray gun that provides stable powder output and good atomization.

Select the appropriate nozzle type and size based on the shape and size of the parts being coated.

Adjust Air Pressure:

Control the air pressure to ensure a uniform distribution of powder particles on the surface of the part. Too high pressure can cause the powder to scatter, while too low pressure can result in uneven coating.

Generally, the recommended air pressure range is 2.0 to 3.5 bar (29 to 51 psi).

Set the Correct Voltage:

For electrostatic spraying, set the voltage to enhance the attraction of powder particles to the part. Typically, the voltage range is 60 to 100 kV.

Excessively high voltage can lead to overcharging of the powder, which may negatively affect the coating quality.

Control the Distance Between the Powder Spray Gun and the Part:

Maintain an optimal distance between the Powder Spray Gun and the part, typically around 8 to 12 inches (20 to 30 cm).

A distance that is too close can result in a thick coating, while a distance that is too far can lead to an uneven coating.

Adjust the Speed of the Powder Spray Gun Movement:

Move the Powder Spray Gun at a steady and moderate speed. Moving too fast or too slow can affect the coating thickness.

Experienced operators can adjust the speed based on the appearance of the coating as it forms.

Use a Coating Thickness Gauge:

Regularly check the coating thickness using a coating thickness gauge to ensure it falls within the target range.

For critical components, set more stringent thickness control standards.

Conduct Test Sprays:

Before starting production, conduct test sprays on standard test panels to verify that the coating thickness meets the requirements.

Adjust spray gun parameters based on the test results to ensure consistent quality during actual production.

Keep the Powder Spray Gun Clean:

Regularly clean the Powder Spray Gun and nozzles to prevent clogging and powder buildup, ensuring the gun operates correctly.

Train Operators:

Provide thorough training for operators to familiarize them with the equipment and process parameters.

Conduct regular skill assessments and retraining to maintain a consistent level of operation.

By implementing these methods, you can effectively control and ensure the desired thickness of your powder coating, thereby improving the quality and performance of the final product.

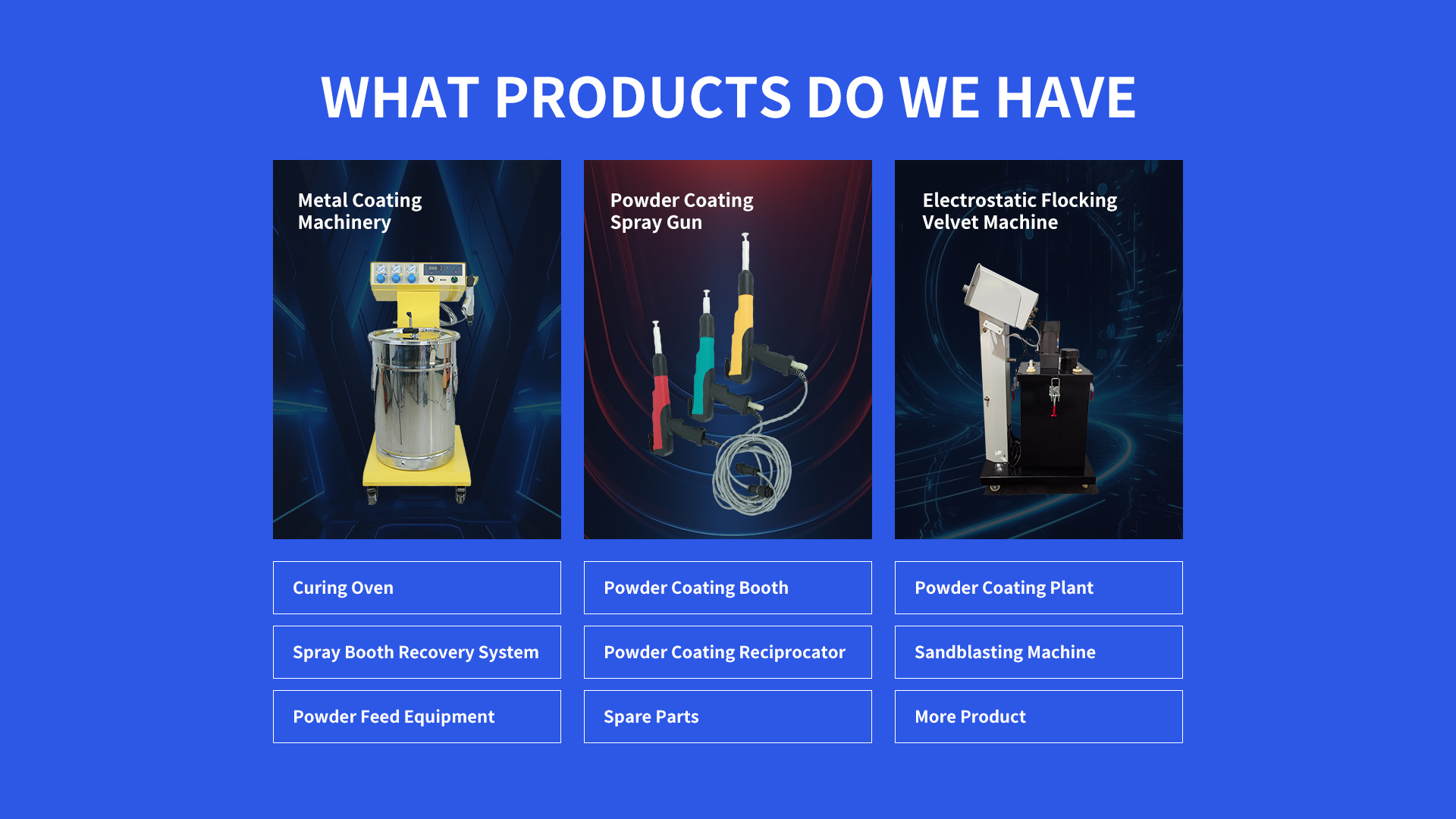

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com